Went through about 150 rounds with the 9mm S&W and switched over to the Rossi model 68.

First shot sounded real lite. Hmmm! Real odd ..... OK...... STOP..... Unload the cylinder and check.

I can see light though the barrel. No obstructions. That was odd!

Lets reload and try again. Second shot was like a cap gun, just a little pop and no recoil. Alright then!!! something is not right. Unload the cylinder and check.

Well look at that!

That is what they call a squib. When a bullet gets stuck in the tube. If you pull the trigger again with one like that you get a big Kaboom and in all likelihood you will damage the firearm and be seriously injured. Good thing I am a bit paranoid about these things and was being careful. OK so we put that one away and go back to the 9mm. Cut out after only a half hour and headed home as I only brought a couple hundred rounds for the 9mm.

This allows the ease of using the .03 cc dipper from the LEE powder measure kit to meter powder and makes for nice light powder-puff target loads.

When I got home I cleared the obstruction easily enough and weighed the offending bullet.

125.7 grains? no wonder!!!

3.2 grains of HP-38 is not nearly enough to propel a 125 grain bullet down the pipe. Using my Hornady bullet puller to remove the bullets off the remaining cases in the box I found 25 of them, one half the box had 125 grain bullets and the powder was consistently 3.2 grains. Somewhere along the way I must have had a major Brain Fart and grabbed the 125 grain pill box instead of the 158 grain box when I was reloading them. Lesson learned.

NOTE: For those not familiar with reloading the it seems counter intuitive to use a less propellant for a heavier projectile, but you have to think of it in terms of maximum allowable pressure in the firearm. See the right hand column in the above image. A lighter projectile offers less resistance than does a heavier one, thus the pressure is less if you use the same amount of propellant as you would for a heavier one. So for lighter projectiles we use a heavier propellant charge or you have the results I experienced here. Also to consider is whether the bullet is cast lead or jacketed as they offer different resistance and this result in different pressures, even if they are the same weight and use same charge of propellant.

On the Hodgdon can it list 3.7 grains of HP-38 for the 158 grain bullets, but that would mean weighing every powder charge individually as ....

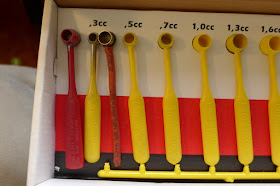

.....one of the issues with using the LEE Powder Measure kit I like, is that it skips a few dippers in the selection. No .2cc came with it so I have an older one I have added. But more importantly there is no .4cc dipper, which is exactly the range useful for the HP-38 powder.

So using a cut down .380 ACP case, a piece of wire and some heat shrink tubing I was able to make one ....

... that consistently throws 4.2 grains of HP-38 powder for the 125 grain pills...

and fits in between the .3 cc and .5 cc dipper

So I did a bit more reloading using my standard recipe.

158 grain lead-cast-semi-wad-cutters on freshly re-sized, re-primed and charged cases

On the press before seating

Seated and crimped, about 5 cents cost compared to 25 cents for store bought

Repeat fifty times

Repeat two hundred and thirty five times

You were lucky it happened at the range...

ReplyDeleteI was lucky I was paying attention and no my usual la-di-dah absent minded.

DeleteI had this happen with some Wolf ammo with a .40 S&W carbine a few months ago, It was right before I left CO. Same thing. First round acted funny. Second one was worse. Looked down the barrel and there were TWO stuck in there. I was kicking myself. New gun. Crap ammo. Never again. Good catch.

ReplyDeleteIt was the first time I have ever had it happen to me. After the first shot I figured there would be a squib but when I checked the barrel was clear and I could see light. By the second one I figured something was wrong with my ammo. It was a real lite report. Just like a primer strike with no powder. When I took the rest of the rounds apart and weighed the components I found out it was my own dumb mistake. I can't blame Tula.

DeleteAre you certain you didn't buy a box of bullets that someone had mixed by accident? I realize that's unlikely, but anything's possible.

ReplyDeleteNo, I don't think it is likely. I can't imagine I'd have walked out of the store with a box with a broken seal. I am real particular about things like that. I do have a box of Berry's 125 grain bullets on my shelf, so in this case I must have made the mistake my self. It is a good lesson on how a simple oversight can result in a bad day. And a good reason to weight check all your components before you load. It was hard to miss when the thing barely popped and there was no recoil on such a light firearm. It makes you pause long enough to realize something is wrong and you stop and check. With two light reports like that in a row I knew something was wrong with my reloads. The correct procedure is to stop, unload the firearm, and check for obstructions and don't try another shot. Breaking the rounds down later revealed my mistake. I own this it 100%. I was lucky. It could have ended a lot worse.

DeleteThat kind of thing happens. I'm always nervous I'll miss one of the casings on the loading block, and put a bullet on top of a primer and an otherwise empty casing. So after I charge the casings in the block, I get my little flashlight and check each one individually.

ReplyDeleteI never really thought about what might happen if you used the the wrong weight bullet. I'm glad you did this post because that's something else I will start checking.

I have the LEE Classic Cast Press you see in the photos. It has the rotating four hole turret. It rotates with every stroke of the lever so you sequentially do each step in the process;

Delete1) de-prime and re-size

2) prime (upstroke on the handle)

3) expand the case neck and charge

4) seat the bullet and crimp

... all without having to touch the case except for putting it in and taking it out of the holder at the beginning and end of the process. It allows for very quick loading. I can do 50 rounds in about a half hour. With an automatic powder measure the process is even faster.

But the disadvantage of this process is it does not allow you to clean the primer pocket between de-priming and priming. So I removed the transmission bar that rotates the turret automatically and do each step separately en mass for all,the cases. This allows me to clean the primer pocket and also charge all cases as one step for all the cases. Disadvantage is you wind up handling the cases a lot more and it is slower but I figure the results are better and It affords more quality control. I have the primed cases inverted in the loading block, (primer up) and I have to flip them over to charge them, so it is quite hard to do a double charge, and it is obvious if you missed one cause you would still be looking at the primer end. After charging I also check with the flashlight to make sure the loads look normal and we don't have a double load or a missed charge. I don't know what I was thinking when I used the 125 grain bullets but all I can conclude is that it was a major brain fart on my part. It was a good lesson. And I'd have had to been asleep to not notice the extremely light report and know something was amiss.

I think with ow my brain works I'd be no good at reloading!

ReplyDeleteIt is not so bad Kev. It just takes attention to detail. Basic principle is heavier bullet less powder, Lighter bullet more powder. You are working against the standard pressure limitations of the caliber. The you can refine for accuracy. It is a satisfying endeavor.

Delete